The concrete industry is just one of many looking at new manufacturing methods to reduce its carbon footprint. These efforts are essential to fulfilling the Paris Agreement, which asks each of its signees to achieve a net-zero carbon economy by 2050. However, a new study from researchers in Japan and Belgium and focusing exclusively on Japan concludes that improved manufacturing technologies will only get the industry within eighty percent of its goal. Using a dynamic material flows analysis model, the study claim that the other twenty percent will have to come from changes in how concrete is consumed and managed, putting expectations on the buyer as well as the seller.

Electric cars, fluorescent lights, water-saving shower heads, these are all examples of efforts to lower our carbon footprint. However, the energy savings are made from the supply side, with companies developing new technologies that reduce the amount of energy consumed for the same amount of use. Notably, they put little demand on the user, who can use the product no differently than before.

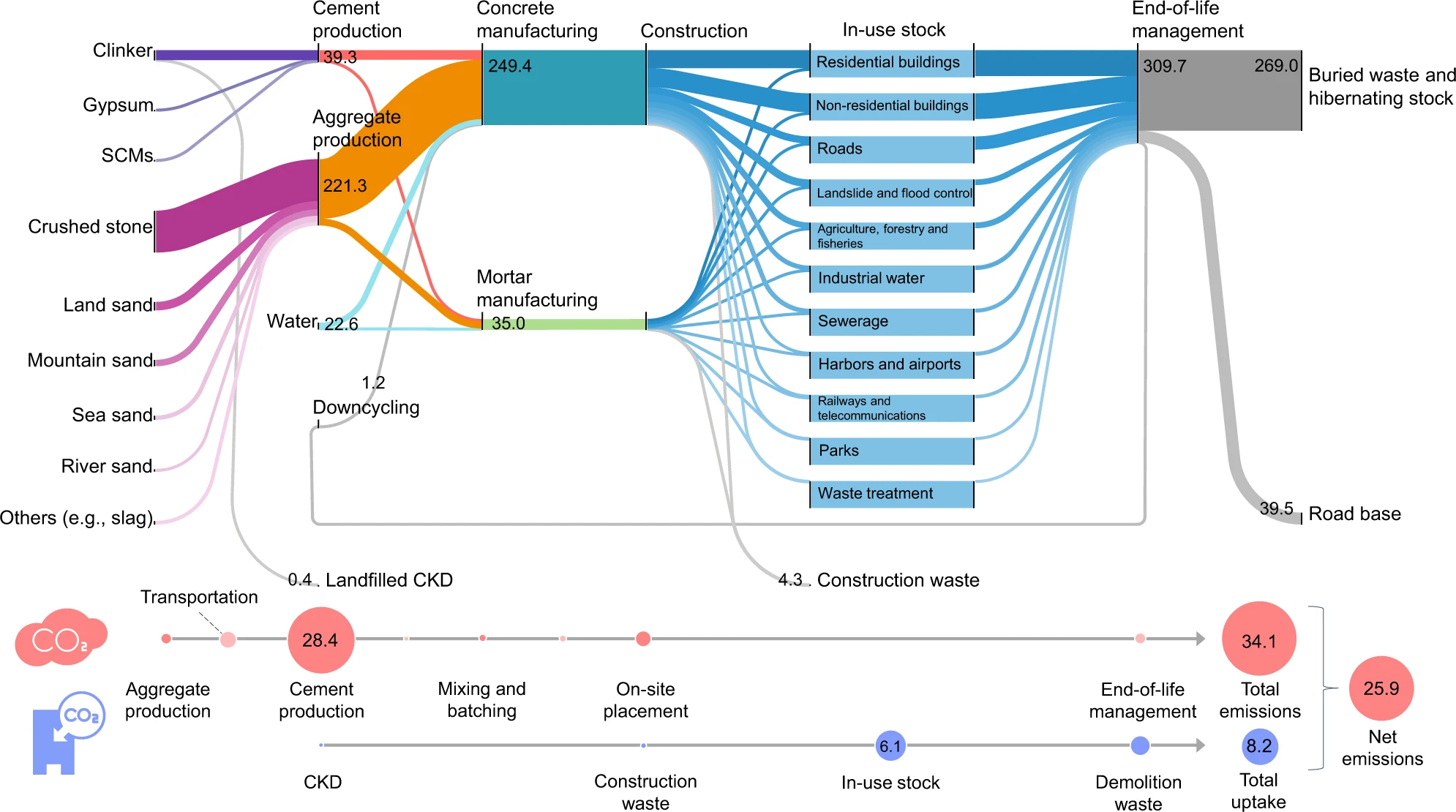

The same holds true for concrete, the most consumed human-made material in the world. Many studies have shown the potential for making the concrete industry more energy efficient through esoteric efforts like “clinker-to-cement ratio reduction”, “cement substitution with alternative binders”, and “carbon capture and utilization”. The problem, explains Dr. Takuma Watari, a researcher at the Japan National Institute for Environmental Studies and lead of the new study, is that supply-side efforts are not enough if nations are serious about achieving net-zero carbon emissions.

“We found that supply-side efforts can at best achieve 80% of the needed reductions. Our research has shown that for net-zero emissions, both supply-side and demand-side strategies are necessary,” he said.

That conclusion came after exhausting all options on the supply side. Watari and his colleagues realized, after examining the cement and concrete cycle in Japan from 1950 to today, that the concrete industry has already implemented effective technologies to reduce its carbon footprint to the point that it cannot be expected to solely take the responsibility.

“We must change not only how concrete is made, but also how it is used,” he said.

Extending the service life of buildings and infrastructure through new design as well as enhancing their multi-purpose use will reduce the demand for concrete. Consumers of concrete, the authors argue, need to view their consumption with more of the recycle, reuse, and reduce attitude applied to household waste.

Obvious targets, they continued, are not just homes, but infrastructure for medical care, transportation, schools and stores. Policies are needed to encourage these consumers to change their behavior. Much like how “energy efficiency” has influenced consumption, societies need to embrace “material efficiency”, which is influenced by design and use, when making their purchases.

The irony, notes Watari, is that the concrete industry, while incentivized to reduce carbon consumption on the supply side, has little motivation in changing habits on the demand side.

“Current profits are directly related to the volume sold. This gives little reason for the industry to promote efficient material use. The change needs to come from policy,” he said.

With appropriate changes to the demand side, the study states that not only will the concrete and cement cycle become more environmentally friendly and the goal of net-zero carbon by 2050 be realized, but there will be benefits for the use of scarce resources such as water as well.

“The most important finding of our study is that there is no ‘silver bullet’ solution. Everyone needs to contribute. Right now, there is too much emphasis on supply-side strategies. To realize net-zero emissions, architects, urban planners, and general consumers must contribute,” said Watari.